Multi cavity hot runner mould

Brand Name:Hamsan Mold

Mold Base:LKM;HASCO;DME,etc

Mold Material:738H

Tolerance:+/-0.01mm

Shaping Mode:Plastic Injection Mold

Design Software:AutoCAD;NX;ProE

Packaging Details:Inner plastic bags+Wooden cases

Delivery Time:25 days

Products Details

ONE STOP SERVICE FOR SIMPLES TO COMPLEX PARTS FROM THE DESIGN PHASE TO MASS PRODUCTION

Product Description:

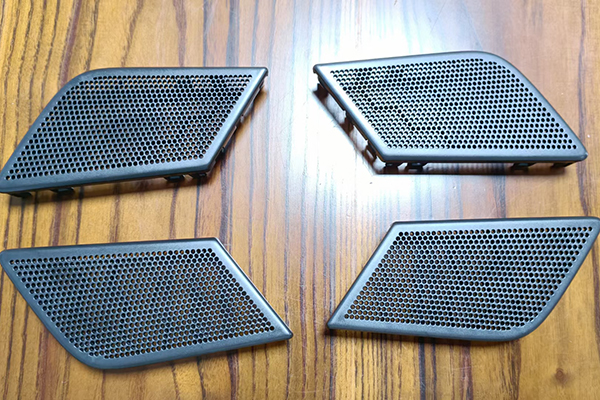

Product name: Multi cavity hot runner injection mould supplier

Mould Material: P20,P20H,718,718H,738,738H,2316,M300,S136,S136H,NAK80,CR12,CR12MOV,SKD11,

DF-2,SKS3,D2,SLD,DC53,H13,SKD61,2344,8407,HD,8418,FDAC,M2,SKH-9,SKH-51,M35

Main Technology: Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc.

Base material: P20, 2738, 2344, 718, S136, 8407, NAK80, SKD61, H13

Product Material: ABS, PP, PC, PA6, PA66, TPU, POM, PBT, PVC,HIPS, PMMA, TPE, PC/ABS, TPV,

Main Technology: Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc.

Equipment: CNC, EDM, Cutting off Machine, plastic machinery, plastic part, etc

Mould Cavity: One cavity, multi-cavity or the same different products be made together

Runner System: Hot runner and cold runner

Finish: Pitting the word, mirror finish, matte surface, striae

Mold Life: 300-500K shots

Mould Precision: +/-0.05mm--+/-0.1mm

Producing Process: Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing

- core processing - electrode machining - Runner system processing

- parts processing and procurement - machining acceptance

- cavity surface treatment process - complex mode Die - The entire mold surface coating

- Mounting plate - mold sample - sample test - sending

Mold package:

1. Clean the set of mold

2. Paint anti-rust oil & grease to inside and outside surfaces.

3. Dry and packing with thin film

4. Place in the plywood or wooden case

Product package:

1. Normal package)Put the product in a PP bag and put them in the carton.

2. Special package) A bubble bag is placed on the product to prevent scratching.

3. Pallet package) Put large products on pallets and ship them together.

4. Can be customized according to customer requirements.

Product Description:

Product name: Multi cavity hot runner injection mould supplier

Mould Material: P20,P20H,718,718H,738,738H,2316,M300,S136,S136H,NAK80,CR12,CR12MOV,SKD11,

DF-2,SKS3,D2,SLD,DC53,H13,SKD61,2344,8407,HD,8418,FDAC,M2,SKH-9,SKH-51,M35

Main Technology: Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc.

Base material: P20, 2738, 2344, 718, S136, 8407, NAK80, SKD61, H13

Product Material: ABS, PP, PC, PA6, PA66, TPU, POM, PBT, PVC,HIPS, PMMA, TPE, PC/ABS, TPV,

Main Technology: Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc.

Equipment: CNC, EDM, Cutting off Machine, plastic machinery, plastic part, etc

Mould Cavity: One cavity, multi-cavity or the same different products be made together

Runner System: Hot runner and cold runner

Finish: Pitting the word, mirror finish, matte surface, striae

Mold Life: 300-500K shots

Mould Precision: +/-0.05mm--+/-0.1mm

Producing Process: Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing

- core processing - electrode machining - Runner system processing

- parts processing and procurement - machining acceptance

- cavity surface treatment process - complex mode Die - The entire mold surface coating

- Mounting plate - mold sample - sample test - sending

Mold package:

1. Clean the set of mold

2. Paint anti-rust oil & grease to inside and outside surfaces.

3. Dry and packing with thin film

4. Place in the plywood or wooden case

Product package:

1. Normal package)Put the product in a PP bag and put them in the carton.

2. Special package) A bubble bag is placed on the product to prevent scratching.

3. Pallet package) Put large products on pallets and ship them together.

4. Can be customized according to customer requirements.